.jpg?width=5760&height=3840&name=steel-pipelines-cables-plant%20(11).jpg)

ASME Section VIII, Division 2 Part 5—Updated Creep Guidelines for 2025: What Engineers Need to Know

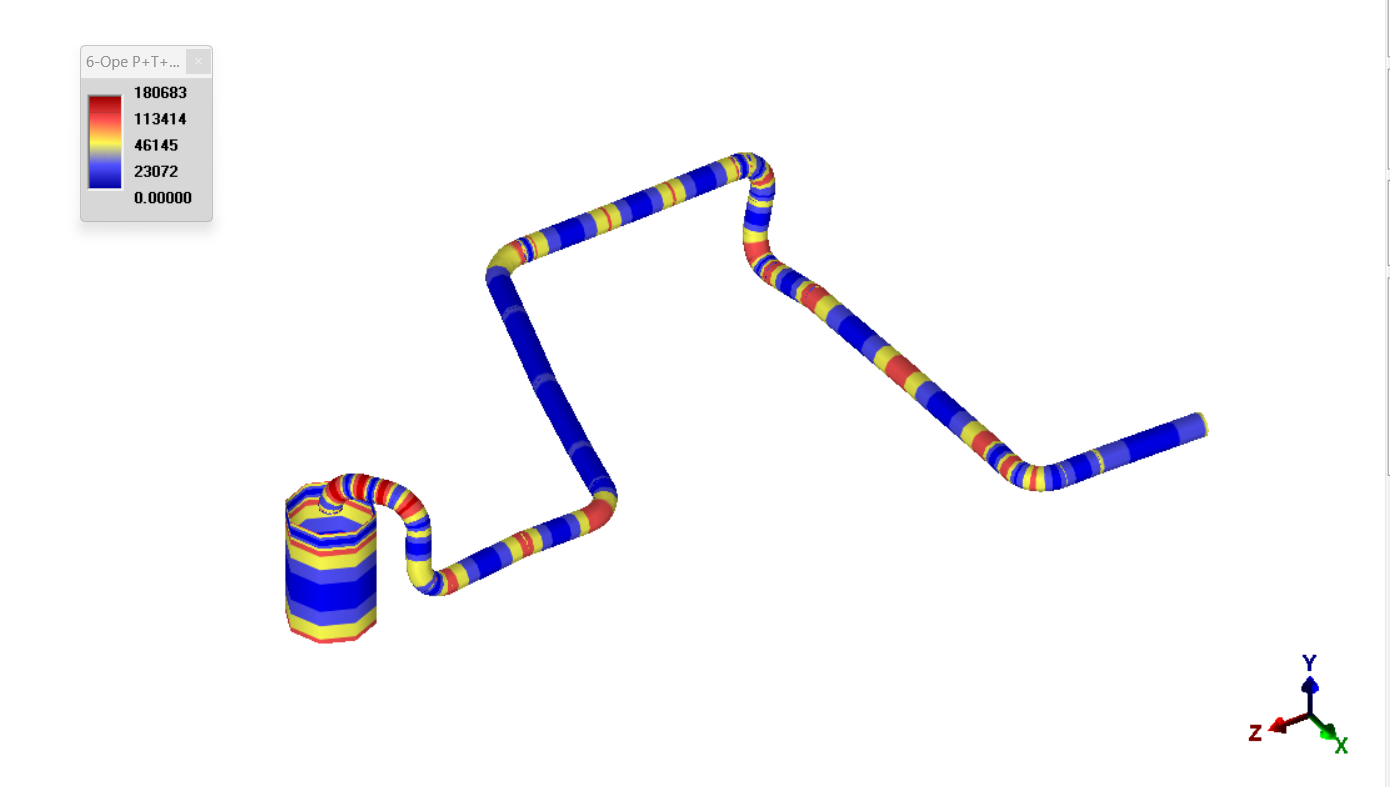

The 2025 Edition of ASME Section VIII, Division 2 brings a number of updates to high-temperature design practices. The changes to Part 5 expand the treatment of creep, clarify the role of primary and secondary stresses in ratcheting, and modernize...

.png?width=2240&height=1260&name=FLANGE%20blog%20banner%20(3).png)

.png?width=1200&height=627&name=Ratcheting%20blog%20image%20(7).png)