4 min read

Advanced Modeling for Complex Piping Systems

Paulin Research Group

Jun 12, 2025 2:17:32 PM

Modern process facilities often face design challenges that extend beyond the limits of conventional piping codes. Systems with large diameter-to-thickness (D/T) ratios, refractory-lined piping, or glass-lined piping require a more detailed approach, where advanced modeling techniques are used to ensure the integrity and reliability of the systems operating in high-stress environments.

From thin-walled stainless steel pipes (large D/T ratio) used in cryogenic temperatures to refractory-lined piping in high-temperature service, these complex designs require specialized analysis. While traditional codes like ASME B31.3 provide an important baseline, they may not capture the nuanced behaviors and risks associated with these demanding systems.

This blog explores how engineers apply advanced modeling techniques to address these challenges and develop safer, more reliable piping solutions for demanding industrial environments.

When D/T Ratios Break the Code

The ASME B31.3 code remains the benchmark for pipe stress analysis in the process industry. However, its limitations become apparent when dealing with piping systems that exhibit large diameter-to-thickness (D/T) ratios, particularly those exceeding 100.

In these regimes, the stress prediction from traditional beam element modeling starts deviating from reality. The assumptions behind classical stress intensification factors (SIFs), sustained stress indices (SSIs) no longer hold up, accurate stress prediction when dealing with high-pressure gas service and thin-walled piping that must perform reliably at cryogenic temperatures. The local deformations and ovalization effects at branch connections and elbows render the theoretical stress intensification factors and sustained stress indices under-predictive. Considering these effects becomes critical to understanding pipe behavior. Stainless systems with large D/T ratios are especially vulnerable to vibration, thermal cycle fatigue, local buckling, and dynamic fluidloads—all issues only marginally addressed by the piping code. For these systems, relying solely on code equations is insufficient and potentially unsafe.

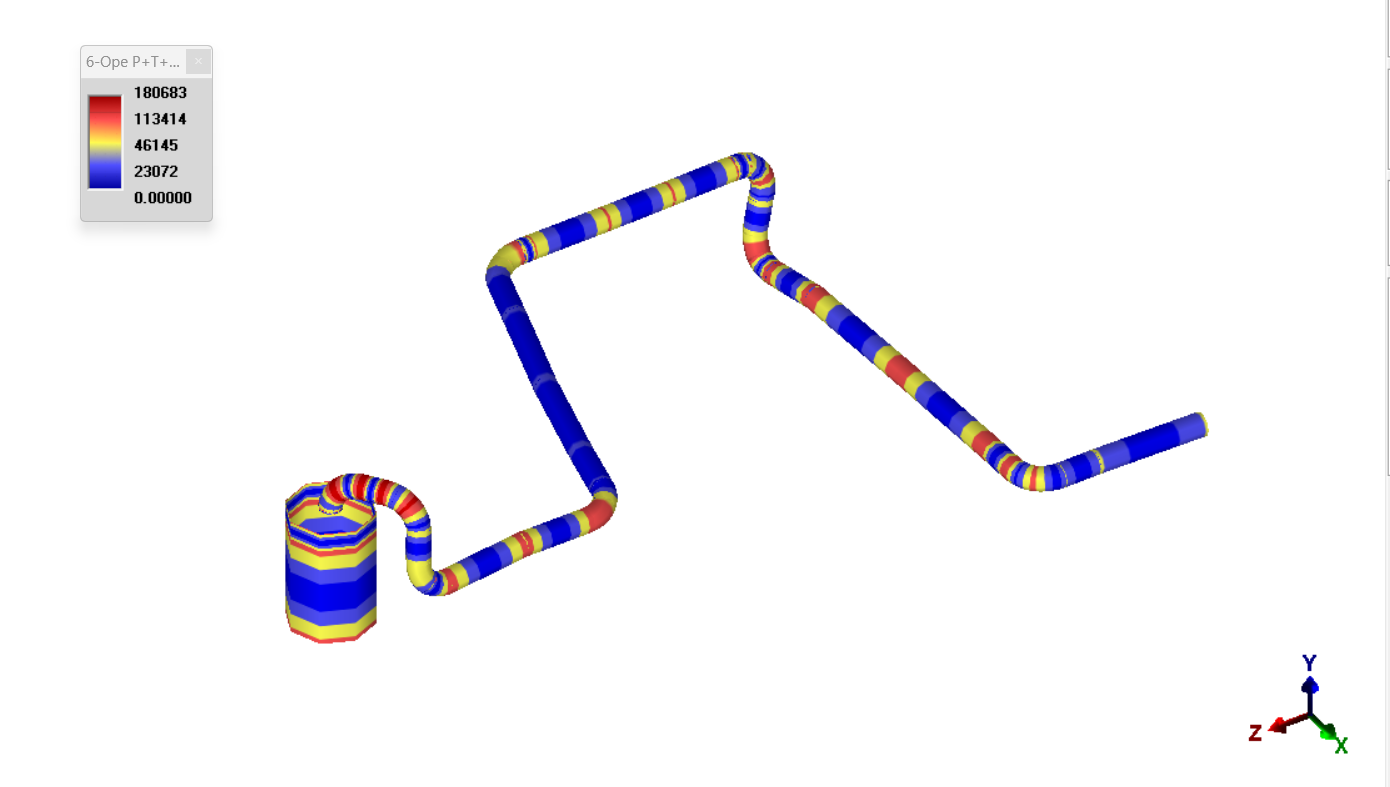

PCLGold fills this gap with enhanced FEA-based modeling that captures:

- Axial Stiffness factors (k-factors), axial Sustained Stress Indices (SSIs), and Stress Intensification Factors (SIFs) beyond the reach of ASME B31J.

- Pressure Sustained Stress Index (SSI) and Stress Intensification Factors (SIF) beyond the reach of ASME B31J.

- Automatic detection of worst-case fatigue ranges, eliminating the need to pre-select load pairs manually.

- Nozzles on vessels and heads

- Locally thickened branch connections – olet type geometries

This becomes critical when engineers must defend design decisions for thin-wall, refractory-lined, or glass-lined systems where even small inaccuracies can lead to large discrepancies in predicted behavior, potentially leading to catastrophic failure.

Beyond Beam: When Beam Models Miss the Mark

In any code-based analysis, engineers are used to simplifying complex geometry into beam models. While efficient for many applications, this approach begins to break down when applied to:

- Large-diameter elbows and tees

- Piping supported asymmetrically or with overhangs

- Systems where axial compressive loads reduce lateral stiffness, especially for vertical risers

PCLGold addresses these issues with an automatic breakdown of intersections, and support for real-world branch connection configurations via integrated FEA modeling that better represents actual industry-fabricated components. This allows engineers to avoid the pitfalls of relying on SSIs and SIFs derived from testing purposely limited to a D/T ratio under 100. Particularly in systems exposed to thermal growth, equipment loads, or accumulated axial force due to friction, the behavior can deviate significantly from what classical theory predicts. PCLGold's path-dependent friction solver accounts for the load sequence—an often neglected but critical aspect of real-world behavior. The result: far more accurate predictions of support reactions, restraint loads, and potential for pipe walk or lift-off.

Refractory Lining: The Missing Layer in Most Models

Refractory-lined piping—commonly used in high-temperature services such as FCC units, flare headers, or SRU lines—poses another modeling blind spot for most conventional stress tools. The presence of refractory introduces non-uniform stiffness, added mass, and complex interaction between the liner and the pipe wall. Worse, refractory is often applied in discrete segments, introducing discontinuities and stress risers that beam models simply cannot accurately capture.

In practice, lining increases flexural rigidity, alters mode shapes, and redistributes load paths in ways that are fundamentally non-linear and geometry-dependent. But in many traditional stress programs, the refractory layer is either ignored, or approximated by uniformly adjusting pipe stiffness, or simply considering the refractory weight only—an approach that ignores the real mechanics at play.

PRG’s tools, including PCLGold, offer a better way forward. Through shell element modeling and more advanced representation of layered systems, engineers can now:

- Capture differential expansion between steel and lining

- Account for loss of lining during operation (intentional or accidental)

- Simulate increased moment resistance and how it redistributes thermal loads

- Assess mode shapes and vibration behavior accurately, considering the true system inertia

- 18+-DOF element modeling that supports ovalization, warping and local bending behavior to properly predict the refractory behavior.

For critical high-temperature lines, this modeling fidelity translates directly into greater confidence in stress margins, support design, and long-term reliability.

Tailored for Complex and Unpredictable Scenarios

While codes like ASME B31.3 serve as essential starting points, advanced applications often require validation beyond what the code prescribes. PCLGold provides that validation, with capabilities specifically aimed at:

- Systems with non-standard tees or fabricated fittings

- Flexibilities. Stress Intensification Factors, and Sustained Stress Indices for nozzles on heads

- Scenarios involving load sequencing, axial friction effects, and non-linear displacement

- Piping subject to fatigue loading, such as cyclic service, startup/shutdown stresses, or slug flow

- Validation of fitness-for-service in borderline D/Tt geometries or when material ordering has reduced the expected safety margin

By automating much of the heavy-lifting—such as inserting proper nodal topology, deriving accurate stiffness values, and analyzing the correct fatigue ranges—PCLGold empowers engineers to focus on interpreting results and making design decisions, not deciding whether the results are based in an incorrect assumption or whether the results are accurate and conservative.

Conclusion

As stainless steel piping systems grow larger, thinner, and more sophisticated, and as high-temperature lined systems become more common in harsh service environments, engineers need tools that evolve with the demands of the job.

PCLGold isn’t just another FEA add-on. It is a purpose-built solution for engineers working in the gray areas where the code ends and engineering judgment begins. Whether dealing with complex geometries, cyclic loads, or critical systems that cannot fail, PCLGold enables smarter, safer designs.

.png?width=940&height=529&name=Copy%20of%20PRG%20Product%20Template%20-%20Gradient%20(1).png)